Rabbit Recombinant Monoclonal Antibody Production

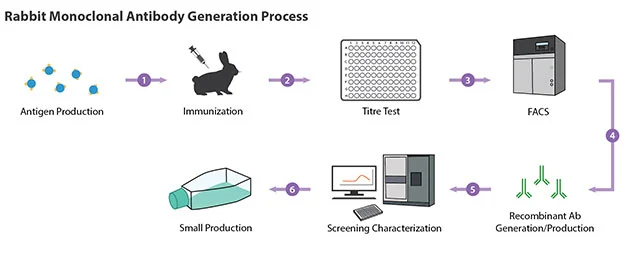

Rabbit monoclonal antibodies are widely recognized and used in research and diagnostics as they are ideal for immunohistochemistry (IHC), flow cytometry, and immunofluorescence (IF). Traditionally, rabbit monoclonal antibody is made from rabbit hybridomas, a process of fusing an antibody-secreting-cell with a rabbit plasmacytoma cell-line. The disadvantage of such a process is that it is time-consuming and the success rate is relatively low. Technology advancements have made recombinant rabbit monoclonal antibody production more achievable and these new methods include the use of (1) phage display library, (2) next generation sequencing of B cells and (3) LC-MS/MS of polyclonal antibody.

The drawback of these new generation processes is the high cost associated and that the resulting artificial antibodies are often limited to specific applications. At abm, our process focuses on generating rabbit monoclonal antibody from primary rabbit plasma cells/plasmablasts. We utilize a single-cell cloning method, memory B cell expansion, and florescence-activated cell-sorting techniques to generate the rabbit monoclonal antibody of interest. Our monoclonal antibody production service offers customized antigen preparation, high efficiency (FACS selection of single cell), stable cell-line generation, and humane treatment of the animal without having to sacrifice the animal.

We offer three standard protocol packages and several extension options. Our complete package includes antigen production and guaranteed polyclonal Western Blot results.

“I am a fan of abm: great product quality, great price, great rewards and great experience.”

Dr. Vincent Emond, Centre de recherche du CHU de Québec CHUL

Additional Resources:

Service Details

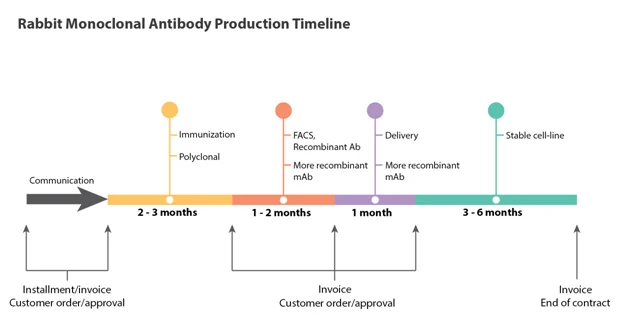

abm’s Rabbit Recombinant Monoclonal Antibody Production Service is divided into different phases, with a non-refundable $4500.00 deposit to cover the material cost to initiate the project. The balance will be due upon completion of individual phases.

The basic package includes Phase I-IV and the complete package includes generation of recombinant antibody secreting stable cell line. Customer can also supply antigen or immunized whole spleen/PBMC/Bone marrow as the starting material for the project, please refer to the notes section for sample requirements.

Core Services

| SERVICE | DESCRIPTION | CAT. NO. | UNIT |

|---|---|---|---|

| PHASE I Services: Antigen Production |

|

C151 | 1 Service |

| PHASE II Service: Immunization |

|

C152 | 1 Service |

| PHASE III Service: Single-Cell Cloning |

Deliverables: DNA sequencing data of variable regions |

C153 | 1 Service |

| PHASE IV Service: Antibody Production |

Deliverables: 25mL of cell culture supernatant of all 3 clones |

C154 | 1 Service |

| PHASE V Service: Stable Cell Line Development |

Deliverables: 25mL of cell culture supernatant of all 3 clones |

C155 | 1 Service |

Add-On Services

| DESCRIPTION | CAT. NO. | UNIT |

|---|---|---|

| Additional Clone(s): Generated from PHASE III-IV | C156 | 1 Clone |

| Large-Scale production of recombinant antibody and purification of antibody by Protein A/G | C157 | 1 Service |

Note:

- * Customers can supply the recombinant antigen for immunization: 3-4 mg of purified protein antigen or 2mg of KLH and BSA conjugated antigen (if the antigen is a small molecule).

- ** Customers can supply immunized whole spleen (in complete growth media) on ice, splenocytes (growth media with 10% DMSO) on dry-ice, fresh whole-blood with heparin on ice, PBMC (growth media with 10% DMSO) on dry-ice, or bone marrow (growth media with 10% DMSO) on dry-ice. Minimal of 10 million cells (splenocytes, PBMC, bone marrow) or 10-30mL of fresh whole-blood is required.

- Customers have the option to start or stop the project from any stages of the mouse monoclonal antibody generation service. Customers will be responsible for the material and labour cost incurred thus far should early termination be requested.

Additional Info

Comparison of Rabbit Monoclonal Antibody Generation Methods

| TRADITIONAL FUSION METHOD | ABM SINGLE-CELL METHOD | PHAGE DISPLAY METHOD | |

|---|---|---|---|

| Lead Time | > 7-8 months | < 6 months | > 8-10 months |

| Cost | > 15,000 USD | ~ 20,000 USD | > 40,000 USD |

| Disadvantages |

|

|

|

| Advantages |

|

|

|

Rabbit Monoclonal Antibody Advantages

| MOUSE | RABBIT | |

|---|---|---|

| Antigen recognition | Limited immune response Limited response to rodent/human Inability to recognize small molecules/peptides Recognize limited epitopes |

Recognize small molecule/peptides Response to rodent/human Recognizes several epitopes Recognize structural variations |

| Affinities | Nanomolar (~10-9KD M) | Picomolar (10-12KD M) to 10-14M |

| Specificity | Medium to High | High |

| Applications | Westerns, ELISA, Flow Cytometry, IP, may not be suitable for IHC, ICC, diagnostic kits | Western, ELISA, Flow Cytometry, IP, excellent IHC, ICC, diagnostic kits |

Documents

Coming Soon

FAQs

What process do you use to generate rabbit monoclonal antibody?

We use FACS to isolate plasma cell, plasmablast or memory B cells. We then clone out and sequence the single antibody secreting cell. In the case of memory B cells, the single memory B cell will be expanded using our proprietary method. We will test the expanded supernatant and clone out any positive clone. After sequence analysis, we will perform transient transfection and collect the culture supernatant to test the antibody’s functionality.

What will be delivered at the end of the project?

For the basic package, we will deliver ~25 mL of cell culture supernatant and the monoclonal antibody sequences. Stable cell-line will be supplied with the complete package. We do offer additional services, including large-scale antibody production, please contact us for more information.

What assay do you use to confirm the functionality of the producedantibody?

For rabbit monoclonal antibody service, we use Western Blotting to ensure the produced antibody have affinity and specificity towards the antigen. Immunohistochemistry (C095) and Immunoprecipition tests (C094) are also available, however are NOT included in the production service. Please inquire with us for further antibody characterization. For rabbit polyclonal antibody services, we guarantee the antibodies will work against the designed antigens in ELISA format. Due to experimental variations, we do not guarantee downstream applications. It is important to understand that the customer takes full responsibility for the antigen designs or delivery.

What is the shortest length peptide that you can produce an antibody against?

To produce an antibody that has specificity and affinity at acceptable levels, we require a minimum of 10 amino acids.

Can you produce an antibody against a native protein?

Yes, however, in order to guarantee the antibody is effective against the native protein, purified native protein must be used for immunization. Recombinant protein or peptide extracts can also be used to immunize, but we cannot guarantee these will be effective against the native protein due to folding and other conformational concerns. Our service guarantees that the immunized protein (native or recombinant) or peptide will be recognized by the produced antibody.

What concentration and amount of antigen is required for production if I am supplying the protein/peptide?

For peptide or small molecule antigens we require at least 2 mg conjugated to carrier proteins such as KLH, OVA or BSA, while if it is a protein, 3-4 mg with concentrations of 0.5-1.0 mg/ml are acceptable.

Do you deliver the cloned expression vectors along with the custom antibody?

No, the customer will only receive the custom antibody and the variable domains sequences. The customer will not receive any antibody expression vectors.

What information do I need to provide to start the project?

Please provide the antigen design or gene accession number and the service you are looking for (i.e. basic, complete or partial) to quotes@abmgood.com.

If I want to deliver fresh whole-blood, when I should bleed rabbit and collect sample after re-boost?

You can collect blood either 7 days after or 14-days after boost.

Citations

| 01 | Ko, FC et al. “PKA-induced dimerization of the RhoGAP DLC1 promotes its inhibition of tumorigenesis and metastasis.” Nat Commun 4:1618 (2013). PubMed: 23511482 |